Contact Us Today

Contact Us Today

Can Insulation Get Moldy?

Mold in insulation is a significant concern for homeowners and builders alike, as it can compromise indoor air quality and the effectiveness of the insulation itself. Understanding the causes of mold growth and how it can be prevented is crucial for maintaining a healthy living environment. This post explores the susceptibility of different insulation types to mold and offers insights on detection and prevention.

What Causes Mold in Insulation?

Mold growth in insulation is often the result of excess moisture, which can come from several sources. Understanding these sources is key to preventing mold:

Leaks:

Roof Leaks: Damaged shingles or improper roofing can allow water to seep into attic insulation.

Plumbing Leaks: Faulty pipes or fixtures, often in walls or ceilings, can dampen nearby insulation.

Foundation Leaks: Cracks or holes in the foundation can let moisture into basement insulation.

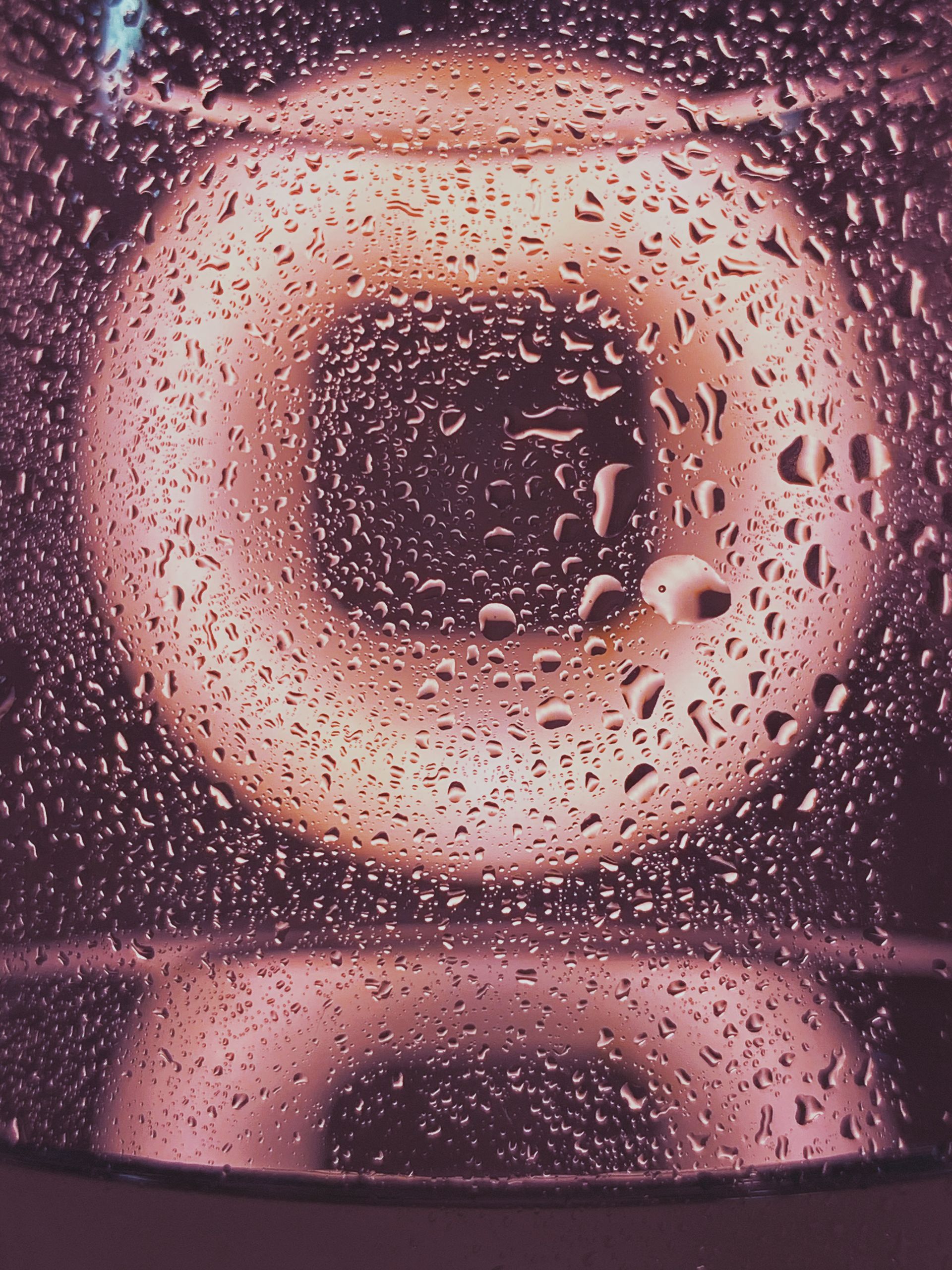

Condensation:

Poor Ventilation: Inadequate ventilation in attics or crawl spaces increases moisture levels, leading to condensation on insulation.

Temperature Differences: When warm, moist air inside the home meets cold surfaces (like exterior walls or unheated spaces), it can condense, wetting insulation.

High Indoor Humidity: Activities like showering, cooking, or drying clothes indoors without proper ventilation can lead to high humidity and subsequent condensation.

High Humidity:

- Climatic Conditions: Humid climates naturally predispose homes to higher indoor moisture levels.

- Lack of Dehumidification: Not using dehumidifiers in naturally damp areas like basements can maintain high humidity levels.

- Indoor Plants and Aquariums: Large numbers of indoor plants or large aquariums can also contribute to higher indoor humidity.

Each of these factors can create an environment where mold can thrive in insulation. It’s important to regularly inspect these potential problem areas and take corrective actions, such as repairing leaks, improving ventilation, and controlling indoor humidity, to prevent mold growth.

Types of Insulation and Their Susceptibility to Mold

Different insulation materials have varying levels of resistance to mold:

Fiberglass Insulation: While the glass fibers themselves do not support mold growth, the backing materials and dust particles trapped within the insulation can. If fiberglass insulation becomes wet, it can become a breeding ground for mold.

Spray Foam Insulation: Closed-cell spray foam insulation is generally resistant to mold because it does not absorb water. However, if the foam is poorly installed, leading to gaps or moisture accumulation, there can be a risk of mold in adjacent materials.

Cellulose Insulation: Made from recycled paper, cellulose insulation is treated with chemicals for fire resistance, but it can absorb moisture more readily than other materials, increasing the risk of mold growth.

Rigid Foam Insulation: Like spray foam, rigid foam insulation generally resists mold growth due to its low water absorption. However, incorrect installation leading to water intrusion can result in mold issues.

Identifying Mold in Your Insulation

For homeowners in Colorado Springs, identifying mold in insulation can be challenging, especially if you're not familiar with the installation process. Here are specific signs to look for in different types of insulation:

Fiberglass Insulation:

- Visual Signs: Check for any discoloration or dark spots on the insulation material, which can indicate mold growth.

- Odor: A musty or stale smell in areas like the attic, walls, or crawl spaces can suggest mold presence in the insulation.

- Physical Deterioration: Fiberglass insulation that appears to be sagging or degrading may have been exposed to moisture, increasing the risk of mold.

Spray Foam Insulation:

- Surface Changes: Look for areas where the foam appears to have shrunk away from framing members, as this can indicate moisture intrusion and potential mold growth.

- Discoloration: Any unusual color changes on the surface of the foam could be a sign of mold.

- Odor: While spray foam insulation typically doesn't support mold growth, a persistent chemical or musty smell long after installation can indicate improper application or moisture problems.

Cellulose Insulation:

- Clumping and Sagging: Cellulose that has absorbed moisture may appear clumpy or sag, suggesting a high potential for mold growth.

- Discoloration and Odor: Look for any signs of discoloration and be attentive to musty odors, as these are strong indicators of mold.

Rigid Foam Insulation:

- Water Stains: Check for water stains or lines on the insulation boards, indicating moisture exposure.

- Surface Irregularities: Any warping or degradation of the board's surface can be a sign of mold or moisture issues.

General Inspection Tips:

- Consistent Monitoring: Regularly inspect areas prone to moisture, like basements, attics, and around plumbing fixtures.

- Professional Assessment: If you're unsure, consider hiring a professional to inspect your insulation, especially in hard-to-reach areas.

- Health Symptoms: Pay attention to any increase in allergy-like symptoms or respiratory issues among household members, as these can be indirect signs of mold presence in the home.

Preventing and Addressing Mold in Insulation

Preventing mold in insulation involves:

- Ensuring proper installation to avoid gaps and leaks.

- Maintaining good ventilation in insulated areas to reduce moisture accumulation.

- Regularly inspecting for leaks or dampness, especially after severe weather or plumbing incidents.

If mold is detected in insulation, it's essential to address it promptly. This may involve removing and replacing the affected insulation and resolving any underlying moisture issues.

Insulation and Mold: Addressing Your Concerns

In summary, mold in insulation is a significant issue that homeowners in Colorado Springs should be vigilant about. Regular inspections and being aware of the signs of mold are key to preventing long-term damage and health issues. Look for discoloration, musty odors, physical deterioration in batts, shrinkage in spray foam, clumping in cellulose, or water stains in rigid foam insulation. Remember, changes in health symptoms like increased allergies can also be indirect indicators of mold problems in your home.

While identifying mold can be straightforward in some cases, it often requires a keen eye and sometimes professional expertise, especially in older homes where insulation might have been in place for many years. If you suspect mold in your insulation or are uncertain about the condition of your home’s insulation, don’t hesitate to seek professional help.

Is your home's insulation in need of an expert evaluation for mold, or are you considering upgrading to newer, more efficient insulation? Contact ProTech Insulation in Colorado Springs. Our team of professionals can provide thorough inspections, expert advice, and quality insulation solutions. We’re here to ensure that your home remains safe, energy-efficient, and comfortable. Don’t let mold compromise the integrity of your insulation and your home's air quality. Reach out to ProTech Insulation today for peace of mind and professional care.

Ready to work with ProTech Insulation?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 111-222-3333

Agency Contact Form

We will get back to you as soon as possible

Please try again later

More Marketing Tips, Tricks & Tools

All Rights Reserved | ProTech Insulation

All Calls Sent To A Qualified Contractor